Okano Electric is the company to design and manufacture the customized factory automation systems.

CONCEPT

Company policy

Okano Electric has been developing our business for more than half a century with the motto of "match the customer's needs". We continue to fulfill our social responsibilities by cultivating excellent independent technology, looking to the bright future, respecting the individuality of our employees, and challenging new possibilities. In addition, our basic philosophy is to contribute to society by providing outstanding products considered safety, quality, and environment aiming customer's satisfaction.

Okano Technology

FA customized solutions

Most of the products made by Okano are the customized systems to match

the customer's requirement and production facility. Since we developed

the world's first analog in-circuit tester which is now the standard for

print circuit board test, we have consistently performed development, design,

manufacturing and installation work, and we have cultivated experience

and know-how to meet customer's needs.

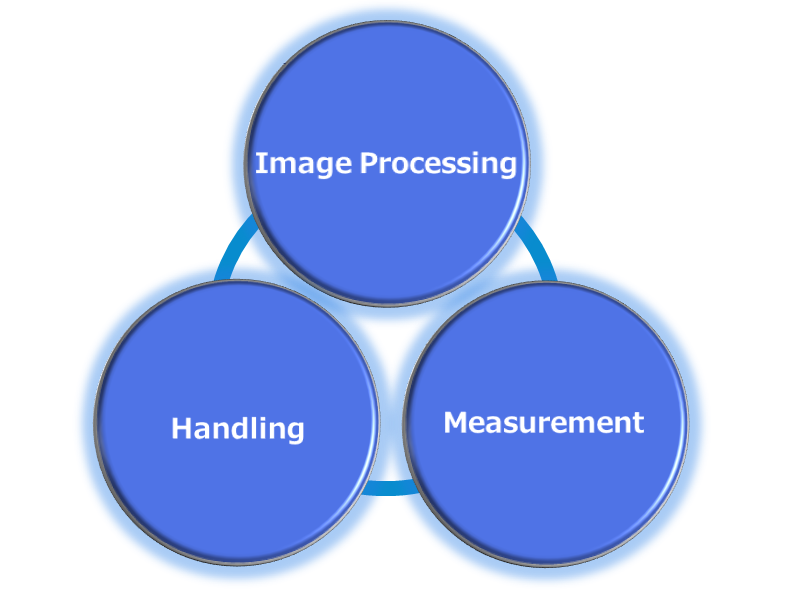

We have delivered our systems with our three main technologies, which is

Okano original "Image processing technology", "Handling

technology" based on our know-hou over 50 years of experience, and

"Measurement technology". Okano has abundant experiences, achievements,

and know-how focusing on the customer's requirement. For instance, we have

provided the handling systems with 1μm placement accuracy according to

our customer's needs. In other case, we have created our original visual

inspection algorithm born from various inspection requirements from our

customers. Therefore, it is possible for us to make our proposal that meet

customer needs. We continue to provide customized systems by making full

use of our outstanding technical capabilities and abundant experience.

Our factory automation systems created by the reliable technology is available

in a wide range of industrial fields such as the electronic / electrical

industry, communication industry such as mobile phones, hard disk industry,

medical industry, tool industry, transportation industry such as automobiles,

and food industry. Also, we are able to provide the solution for enhancement

of the customer's facilities with our systems.

Corporate history

- 2018

- Okano Electric 50th anniversary

- 2015

- Hiroaki Okano became CEO/President in our company.

- 2008

- Increased our sales for the customers mainly in semiconductor, electronic components, and automotive selling the visual inspection machines, assembling machines and handling systems

- 2007

- Succeed to expand our business at the field of Factory Automation

- 2006

- Started to sell"OVT-2240" which is inspection machine with the side camera to check the chip mounting on the printed circuit board

- 2005

- Started to sell "OVT series equipped 3 million pixel color camera which was the industry's first application.

- 2003

- Started to tie up with Shindenshi Co.,Ltd to enhance and upgrade "OVT series"

- 2002

- Started to Development, design, and produce our handligy sysmtem "OVH series". "ZPC-5000" development / production was started.

- 1998

- Started to Develop and produce the in-circuit tester "ZPC-2000/3000"

- 1997

- Development, design and production start of the four-sided chip inspection

machine "OVS series".

"ZPC-1500" development / production start. - 1996

- Increased our designers and engineers to respond the increased inquiries

of the assembling machines, visual inspection machines, characteristics

test machines and handling machines.

We developed the "ZPC-1000" series / production start. - 1995

- Established four domestic offices and 8 overseas bases. In addition, the circuit tester "FA-931" that employs a personal computer was started to develop and produce.

- 1994

- Development, design and production start of FA machine corresponding user nees.

- 1993

- Development and production start of the flying prober tester with the Linear Surface Motor(Patented)/ PBC Bare board tester / SMT chip mounter.

- 1988

- Development, design and production start of OCM series "OCM-8400IIQF" equipped with the function of the odd-shaped parts and IC mounting, which was adopted the advanced image processing technology with high-precision and high speed.

- 1987

- Development / production start of the ultimate in-circuit tester "OIT-510Z" of the Z series.

- 1986

- Development of the the ceramic substrate insulation and resistance testing machine "BT-861".

- 1985

- New office inauguration. After that, new plant inauguration in 1988.

- 1984

- Because OCM series of strong, development / production start the peripheral device (loader / unloader / intermediate conveyor / reversing machine)

- 1982

- Significantly sales increased of "OIT-510N" and started to develop the peripheral units equipped with OIT-510N.

- 1980

- Exported an in-circuit tester in Southeast Asia and European countries and expanded overseas business. Development and production start of the chip mounter "OCM-8000" in order to change the board sufface mounting method.

- 1978

- Board pattern tester "BT-1000" development / production start. We developed the "OIT-510".

- 1977

- Developed the world's first board circuit inspection machine Analog in-circuit tester "OIT-500" and started production. Started to sell the pin board for in-circuit tester (inspection jig) at the same time.

- 1974

- Started production of the jig for board operation check "Unit checker" and the contact probe.

- 1972

- Newly established the three plants along with mounting board business expansion and our employees were increased.

- 1969

- Okano Electric Co., Ltd. established. Primarily started the assembly of the built-in substrate for the consumer electrical products (acoustic equipment / computer / color TV, etc.).

バナースペース

OKANO ELECTRIC CO.,LTD.

〒203-0003

2-8-18 KANAYAMA-CHO HIGASHIKURUME TOKYO JAPAN

sales@okano-denki.co.jp

TEL +81-42-471-3316

FAX +81-42-474-1675